Historically the treatment of polymer blends expounded on in textbooks treated individual domains within blends as retaining their bulk component properties such that to a first approximation the blend’s macroscopic properties can be considered to be a weighted average of the individual component properties based on the fraction of each component. However, it has been recognized for some time that the morphology of the blend plays a large role in determining the blend’s macroscopic properties and material performance (a central premise behind structure-property relations). Yet, even in this treatment the material differences are frequently assumed to be localized at the polymer-polymer interfaces between domains with the domains themselves still thought to exhibit bulk properties.

It is common to think that material properties follow the local composition, which transitions sharply within a few nanometers at the interface between immiscible polymers. However, this traditional view is not consistent with studies on polymers in nanoconfined systems such as thin films which over the past two decades have demonstrated large property differences caused by interfacial perturbations when film thicknesses or domain sizes become comparable to approximately 100 nm (see Nanoscale property changes in thin polymer films). Given the prevalence of new synthesis and processing technologies that can create so-called nanostructured blends with domain sizes less than 100 nm, there is a pressing need to understand how local properties change across and near polymer-polymer interfaces.

Recent work from our lab has uncovered broad profiles in local Tg(z) across glassy-rubbery polymer interfaces demonstrating glass transition dynamics can become coupled between neighboring polymer domains over long distances. Current efforts in our lab are aimed towards understanding the cause of this unexpected phenomenon.

The glass transition temperature (Tg) is a fundamental property that defines a material’s transition on cooling from an equilibrium rubbery melt (typical rubbery modulus ~MPa) to a nonequilibrium glassy solid (typical glassy modulus ~GPa). We are interested in understanding how the local value of Tg and other related properties change across a polymer-polymer interface from one domain to another.

Communication: Experimentally Determined Profile of Local Glass Transition Temperature Across a Glassy-Rubbery Polymer Interface with a Tg Difference of 80 K

Roman R. Baglay and Connie B. Roth,

Journal of Chemical Physics 2015, 143, 111101.

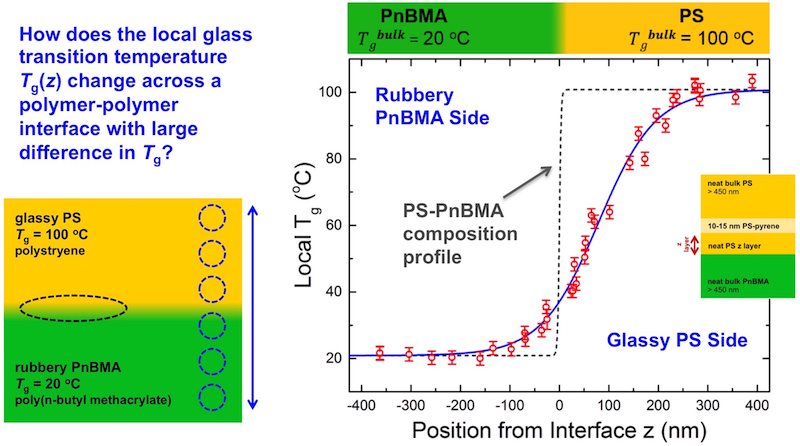

Within a glassy-rubbery model system, we have measured the dynamical profile of the local glass transition temperature Tg(z) as a function of position z across a polymer-polymer interface using a localized fluorescence method. A canonical glassy polymer, polystyrene (PS) with nominal Tg = 100 °C, is placed in contact with a canonical rubbery polymer, poly(n-butyl methacrylate) (PnBMA), with nominal Tg = 20 °C. Both domains are made large enough to avoid other interfacial interactions associated with the sample boundary. The local Tg(z) of 10-15 nm thick pyrene-labeled layers are then measured at different positions z from the polymer-polymer interface (z = 0) within both domains on either side of the interface. Clearly the local Tg(z) value will transition from one extreme to the other: from 100 °C far from the interface on the glassy PS side to 20 °C far from the interface on the rubbery PnBMA side. What is surprising is that the dynamical Tg(z) profile is very broad, spanning 350-400 nm from one bulk Tg value to another, not at all matching the composition profile as would be expected based on traditional textbook teachings. In addition, the dynamical Tg(z) profile is highly asymmetric, spanning much further into the glassy PS side than the rubbery PnBMA side. Theoretical considerations suggest this dynamical length scale should be related to that associated with cooperative motion in glasses.

Local Glass Transition Temperature Tg(z) of Polystyrene Next to Different Polymers: Hard vs. Soft Confinement

Roman R. Baglay and Connie B. Roth,

Journal of Chemical Physics 2017, 146, 203307.

Local Glass Transition Temperature Tg(z) Profile in Polystyrene next to Polybutadiene With and Without Plasticization Effects

Benjamin L. Kasavan, Roman R. Baglay, and Connie B. Roth,

Macromolecular Chemistry and Physics 2018, 219, 1700328.

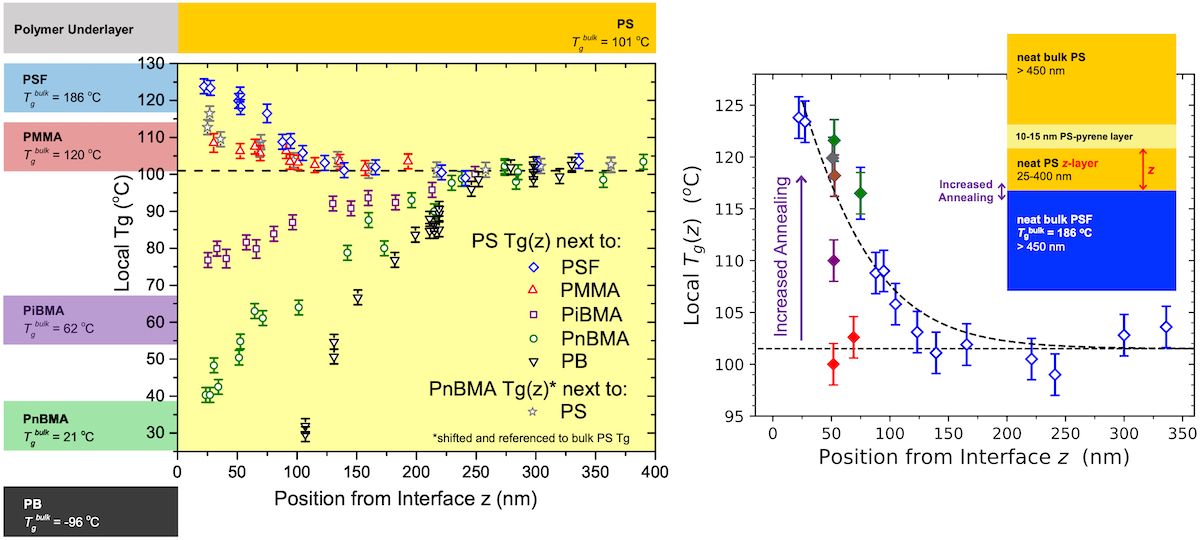

We have demonstrated that this broad and asymmetric Tg(z) profile is common to a range of polymer systems. For polystyrene (PS) domains placed next to a variety of different weakly immiscible polymers with Tgs both lower and higher than that of PS, we find that the local Tg(z) profile exhibits a common behavior consistently recovering bulk Tg at a distance of z = 100-125 nm from the interface when PS is next to a “hard” versus z = 225-250 nm when PS is next to a “soft” interface.

One of the key findings from our 2017 Journal of Chemical Physics paper is that the broad, asymmetric Tg(z) profile only develops when the polymer-polymer interface is annealed to equilibrium. If the measurement is done with minimal of annealing of the interface, the Tg(z) profile is much sharper. This indicates that some factor(s) during polymer-polymer interface formation causes this broad coupling of dynamics across the interface. We pursued a series of experiments to decipher which of these factors was important: broadening of the interface, chain connectivity across the interface, and roughening of the interface. These were recently reviewed in:

Polymers Under Nanoconfinement: Where Are We Now in Understanding Local Property Changes?

Connie B. Roth,

Chemical Society Reviews 2021, 50, 8050-8066.

Local Glass Transition Temperature Tg(z) Within Polystyrene Is Strongly Impacted by the Modulus of the Neighboring PDMS Domain

Yannic J. Gagnon and Connie B. Roth,

ACS Macro Letters 2020, 9, 1625-1631.

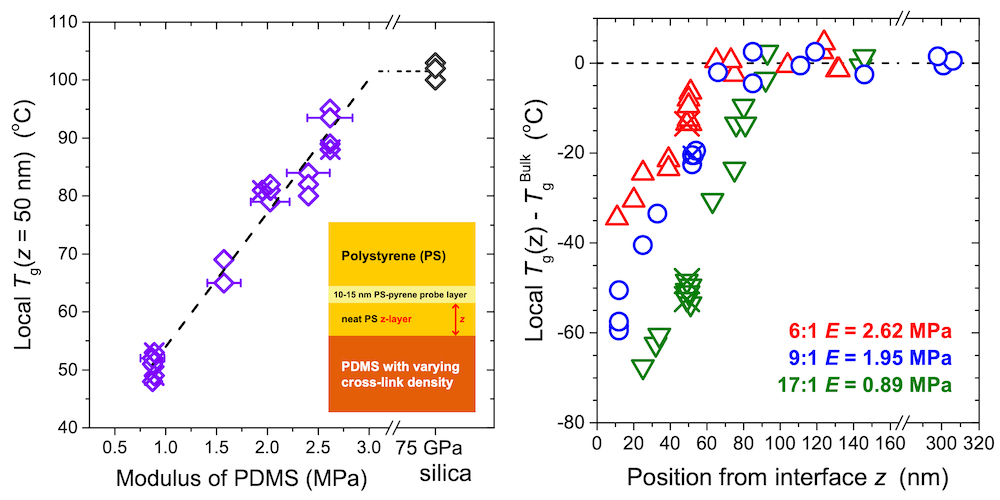

The differences between hard versus soft interfaces, along with theoretical efforts in the literature, suggests that the modulus of the neighboring domain may also play an important role in determining this behavior. As such we have collected Tg(z) profiles in polystyrene (PS) next to polydimethylsiloxane (PDMS) with varying crosslink density. The local Tg(z) in PS at z = 50 nm from the PS/PDMS interface varies by more than 40 K with varying PDMS modulus from 0.9 to 2.6 MPa. However, the Tg(z) profiles also persist out to a much shorter distance (z = 65-90 nm), which we attribute to the much narrower polymer-polymer interface formed between this strongly immiscible system, as the χ parameter for PS/PDMS is an order of magnitude larger that the weakly immiscible systems shown above.

Experimental Study of the Influence of Periodic Boundary Conditions: Effects of Finite Size and Faster Cooling Rates on Dissimilar Polymer-Polymer Interfaces

Roman R. Baglay and Connie B. Roth,

ACS Macro Letters 2017, 6, 887-891.

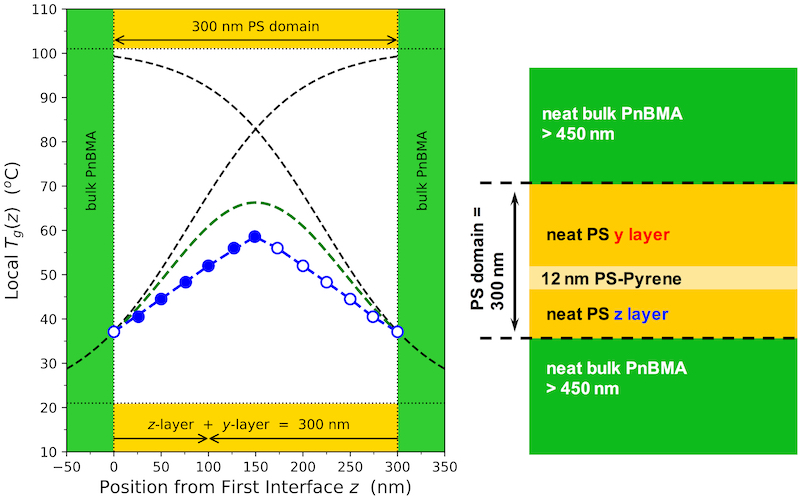

Another key factor we are pursuing with ongoing work is the role of finite domain size. Our first look at this found that the presence of a second PS/PnBMA interface already began perturbing the measured Tg(z) values in PS when the PS domain became less than approximately 400 nm. The Tg(z) profile across a 300 nm PS layer did not correspond simply to the additive effects of two PS/PnBMA interfaces suggesting that finite size effects also modify the behavior. We believe understanding these effects is essential to bridging the gap between our earlier results on single interfaces with semi-infinite domains and block copolymer systems.